Latest News

-

Viking Partnership Packs a Punch

November 7, 2023

The Vikings might once have had a reputation as seafaring marauders, but today some of their namesakes are making waves in other ways. -

Hiber launches Satellite-Enabled Well-Mon

July 6, 2023

HiberHilo optimises production, reduces downtime, and improves the safety and sustainability of remote oil and gas wells. -

Introducing the June edition of our Austr

June 7, 2023

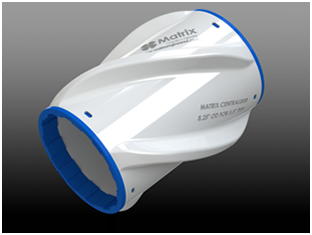

Introducing the June edition of our Australian Newsletter WELLStream, where we introduce A Step Change in Wireline Safety Valve Technology, FlowGARD™

YouTube Channel

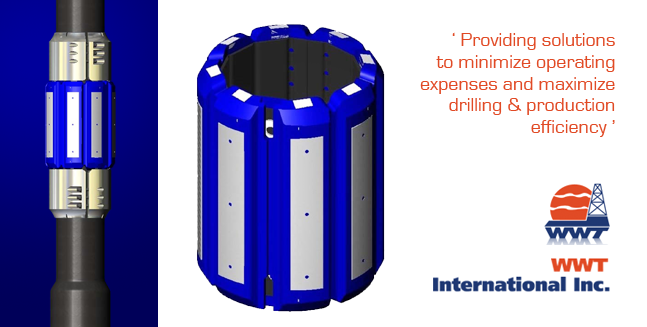

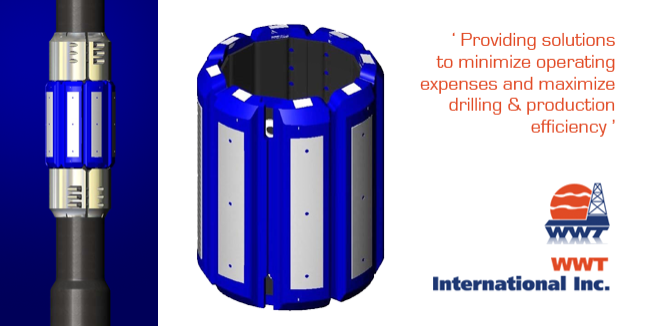

WWT Installation on West Epsilon February 2010 (Shown)

www.youtube.com/watch?v=QRYgzQFosh4

Watercut Australia

https://youtu.be/Q2JV_6Lj1ik